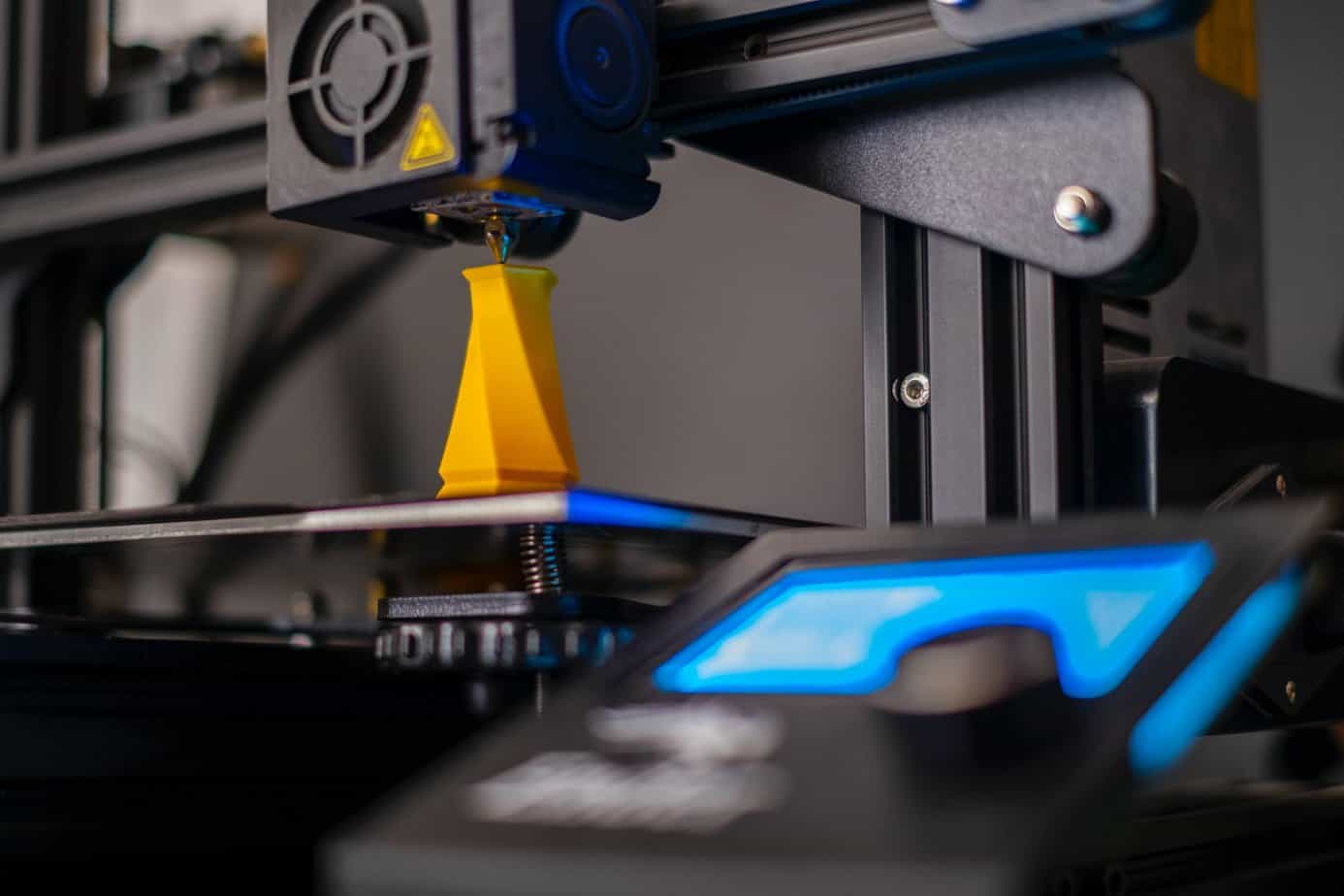

3D printing technologies are improving every day. Probably in the not too distant future 3D printers will be considered as important an achievement of mankind as, for example, the creation of the Internet. Scientists, investors and even NASA scientists see great potential in these devices. We tell you about the most interesting applications of 3D printing to date!

The company “3D Systems” has achieved astonishing success when it comes to printing various food items. The ChefJet device is used to produce chocolate and candy in various flavors. The apparatus works on the same principle as other 3D printers. The difference is, it prints using sugar or icing. Representatives of the company assure that they are able to produce figures with complex and sophisticated shapes, so their printer will be popular in restaurants.

The medical world is also reaping the benefits of 3D printing technology. In 2012, an 83-year-old patient was implanted with a titanium implant made using the so-called “incremental method,” which involves locally melting powdered material with a laser. The procedure went well and doctors began extolling the virtues of implants created through the 3D printing method. There were no complications during the operation. The very next day, the patient was taking meals and talking independently.

A group of students from the Institute of Science and Technology in the city of Changsha has constructed a car using parts made using spatial printing. The car reaches a speed of 100 kilometers per hour and weighs only 220 kilograms. Admittedly, the assembly of such cars costs much more than industrial production, nevertheless, the scientists expect their production costs to fall in the coming years.

An exoskeleton has been created at the Alfred DuPont Children’s Hospital in Philadelphia to help disabled children. The exoskeleton increases muscle strength so children can move freely. It all started when two-year-old Emma couldn’t use her exoskeleton because it was too heavy. The team of scientists then created its lighter analog with the help of 3D printing technology.

Designers from the European Aerospace and Defence Group (EADS) have developed a unique bicycle from layers of fused nylon. The technology used in this case, called additive layer manufacturing (ALM), involves layering thin layers of nylon with the help of high-powered lasers until the desired shape and thickness is achieved. The airbike presented by the scientists is completely functional despite the fact that even the pedals and chains were created using 3D printing.

3D printing technology is already being used by leading manufacturers to produce tools with narrow applications. These include ordinary DIY wrenches, screwdrivers and hammers, but also surgical scalpels. Experts assure that in about 5-10 years customers will be able to design their own tools at home or order them from manufacturers.

main photo: unsplash.com/Osman Talha Dikyar