Sponsored article

In a world where precision is paramount in many operations, the accuracy of measuring tools used in various industries significantly determines the quality and efficiency of the production process. Our exploration of the role of precision in measuring instruments serves to highlight the importance of these tools and demonstrate their implications for industrial applications. Join us as we delve into why precision is essential, how industries rely on it for optimal outcomes, and how to address common challenges that come with ensuring precision.

The necessity of precision in measurement tools cannot be understated. Precision is key to achieving reliable accuracy in different industries, from agriculture to pharmaceuticals. By ensuring your measurement tools are precise, you ultimately safeguard the quality of your operations; any errors or miscalculations can have costly impacts. The measuring vessels from BOTT, for instance, are renowned for their precision, helping to streamline processes and enhance efficiency.

These specially designed tools underscore the importance of accuracy in measurements, boosting the reliability of outcomes and helping industries abide by set standards. Precision in tools like measuring cups and vessels isn’t just a nice-to-have. It’s a necessity. It’s the key to efficiency, safety, and reliability in operations, making them indispensable in several industries. Using precision measurement tools is therefore not just a choice, but a necessity for any industry aiming for accurate results and consistent quality.

Industries across the globe demonstrate a profound reliance on high precision measuring tools to secure their optimal production outcomes. These pivotal instruments underpin every aspect of production processes, from fostering product consistency to maintaining quality assurance, their impact is inescapable. Examples include:

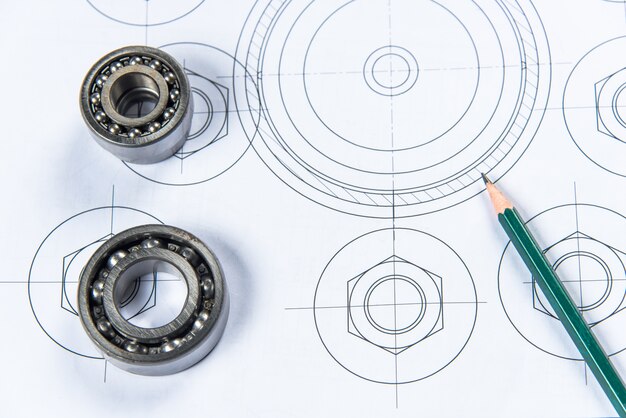

Automotive industry: where precision measurement instruments like micrometers and calipers ensure parts meet exact specifications.

Electronics: small components necessitate high precision measuring for a faultless fit.

Construction: tools like laser distance measures help construct accurate and safe structures.

These diverse examples showcase how integral high precision measuring tools are within industries, helping them meet and exceed their production goals through meticulous measurement. Accuracy undoubtedly determines the very success of every industry, emphasizing the critical role precision tools play in our industrial ecosystem.

When it comes to precision in measuring tools, various challenges often impede optimal accuracy. These challenges can include environmental factors, user error, and the natural wear and tear on the tools themselves. Each of these factors contributes to a potential margin of error, which can significantly impact any given project or task.

Addressing the issue of precision in measuring tools necessitates a combination of routine calibration, proper handling, and the usage of high-quality tools. This solution-oriented approach ensures that the margin of error remains as minimal as possible, and that all measurements taken are as accurate and precise as possible.